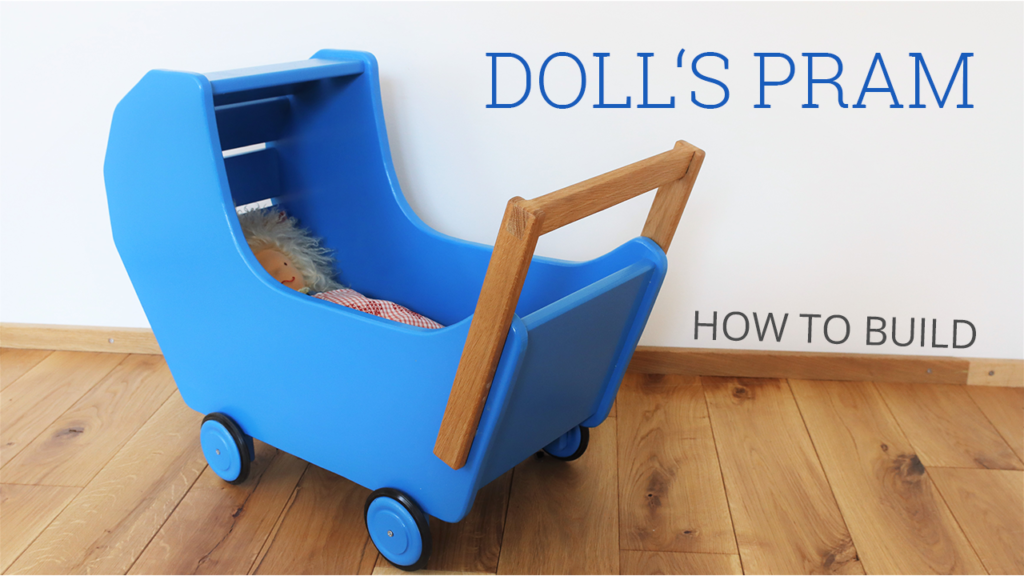

Due to the Corona lockdown, I was not able to get the doll’s pram my daughter wanted for her birthday. At the last minute, I decided to build one myself and here I show you how I did it:

Tools I used

- Track Saw

- Jigsaw

- Table Saw

- Band saw

- Pull Saw

- Domino

- Round over bit

- Flush trim bit

- Random orbital sander

Materials and supplies

- 18mm (3/4″) birch plywood

- Scrap piece of Oak

- 5x30mm Dominos

- Primer

- Waterbased Laquer (sky blue)

- 100mm (4″) wooden toy wheels

- 4 x M4x50mm (2″) screws, washer and locking nuts

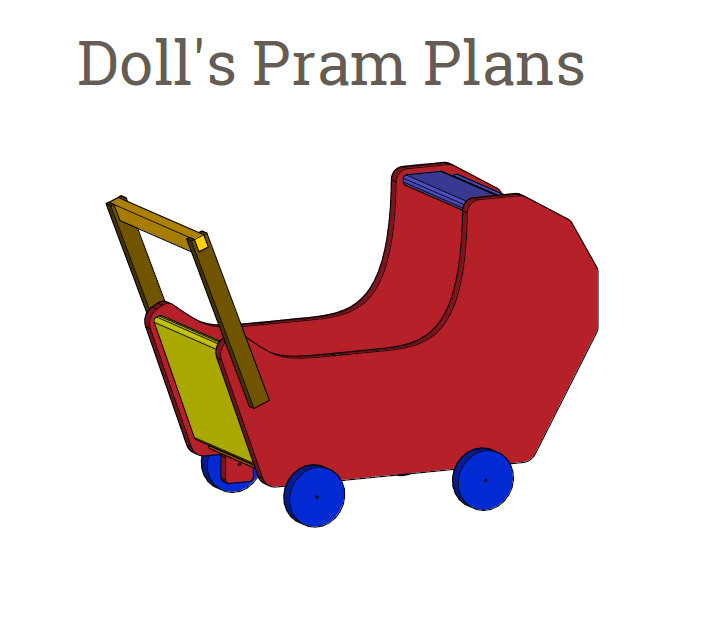

Get the full set of plans and the printable full-sized template

Breaking down the plywood

I started this project by breaking down 18mm birch plywood into manageable pieces. When cutting plywood in my driveway I like to use rigid foam insulation sheets to lift the plywood off the ground.

Back in the shop, I ripped a clean edge on each piece. After setting up my ripping fence, I used this edge against the fence and cut the pieces to width. With the crosscut fence I could then saw them to length. All the connecting pieces are cut to size and it was time to make the sides of the doll’s pram.

Template for perfect sides

The sides give the pram its look and hence I wanted them to be close to perfect with sharp and accurate lines. I printed out the design I worked out at the computer on multiple A4 sheets and could tape them up after figuring out how they come together. I placed the template on a piece of 12mm MDF and secured it with tape. Spray adhesive would have been way better but I forgot to stock up.

With the jigsaw, I cut out the template very slow and carefully. This took some time, but since the template determines the shape of the sides I didn’t rush it. Because I had to saw straight through the tape that secures the paper to the MDF I had to tape it again.

Pro tip: Do not saw into your workbench. After removing the paper template I filed out a few bumps I’ve created with the jigsaw.

Then I placed the MDF template on my plywood and traced the shape of it with a pencil. 2 times. At the table saw I cut them apart. Note the super cool angle I get for my Instagram with the tripod on the sliding table.

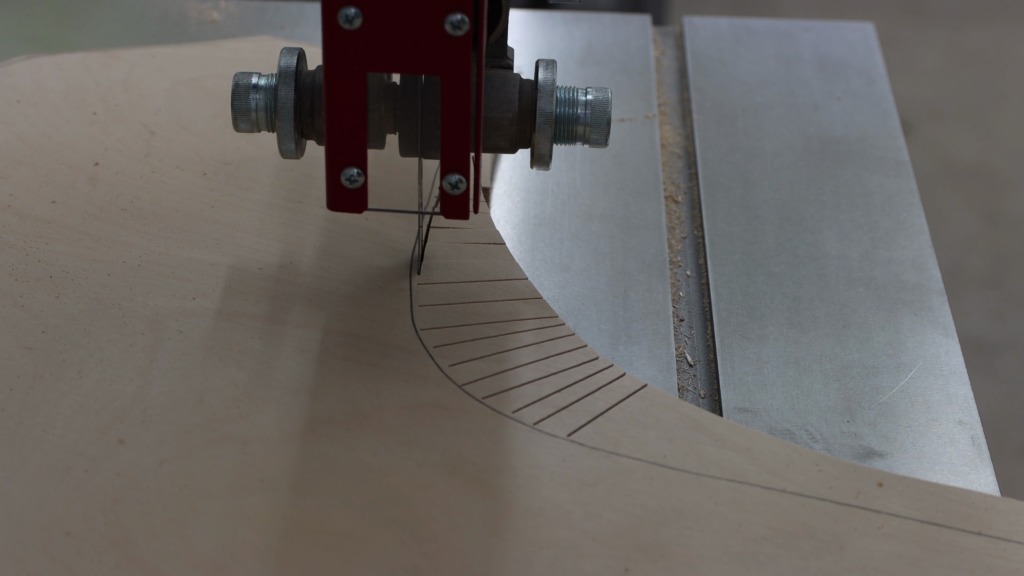

At the bandsaw, I roughly cut the sides while making sure I stay close and outside of the lines. For the tight inside curves, I made a bunch of relieve cuts first. This saved me the hassle of changing to a smaller band saw blade.

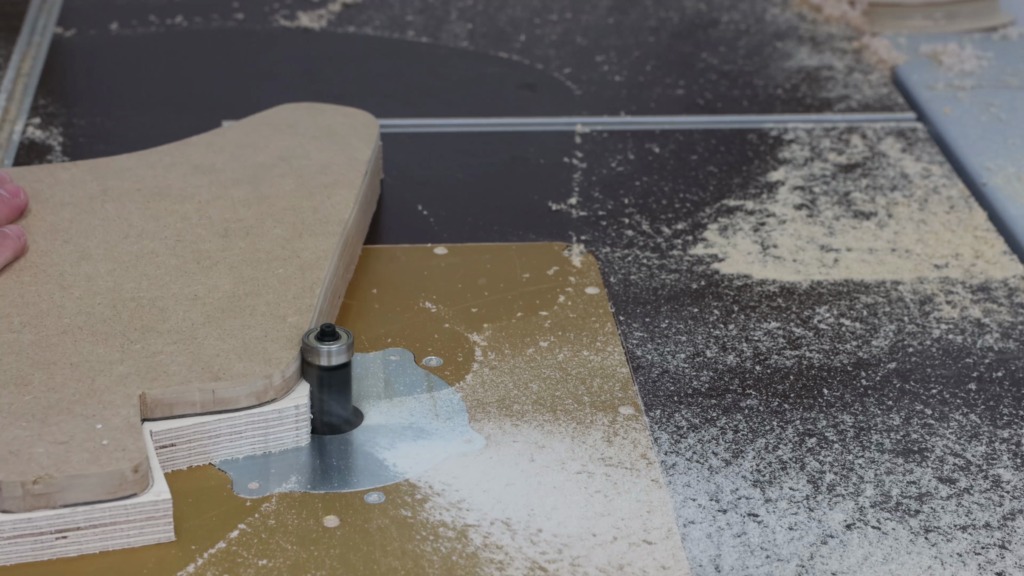

To secure the MDF template to my plywood blank I used double-sided tape. With my big flush-trim bit, I cleaned up the plywood sides and ended up with 2 perfect copies of each other after removing the template.

Connecting the two sides

Spacing the connecting pieces equally apart and parallel to the edges of the sides is not so easy on a rather complex shape. The pieces should be offset by 10mm from the edge. Since they are 18mm thick I get the inside by making a mark parallel to the edge at 28mm. From the intersection of two marks, I measured 5mm in each direction and got the corner of the connecting pieces. After repeating it for every connecting piece I could place them equally.

With the head of my combo square slid up to the corner I marked the location for the dominos.

I used the 5mm bit for 5x30mm Dominos and placed the Domino with the base plate right to the marks. Free-hand routing the dominos worked pretty well for me, but you could also clamp a guide in order to make the process more precise and easier. With the fence set for 20mm boards, I routed the slots into the connecting pieces. Why 20mm when I am using an 18mm board? Because by registering the base plate to the inside edge of the connecting pieces on the sides the center of the Domino measures 10mm from the edge. With the fence at 20mm, the center of the bit is also 10mm adjacent to the edges.

Of course, I couldn’t resist and had to assemble the pram… But getting these dominos out again isn’t effortless.

Don’t worry, you do not need a Domino for this project. Although I found it to be the best solution for me to use it in this project, you can go with standard dowels, pocket holes, or just regular screws. It really comes down to what you are comfortable with and which tools you have at your disposal.

The handlebar

For the handlebar, I used solid oak so that it has a bit of contrast. At the jointer, I jointed one face and one edge. Then I marked the two jointed faces so that I don’t get mixed up when resawing.

Speaking of resawing. I set my guidepost to the lowest position possible and adjust my fence 2 to 3mm proud of my final thickness. With a sharp blade, a slow feed rate, constant pressure against the fence, and my very fancy scrap piece push sticks, I get a decent result almost every time.

Next, I plane the boards to their final thickness of 18mm. At the table saw I cut the boards to their final dimensions.

This is how the 3 pieces should come together. Two side pieces and one crosspiece. I mark their orientation with the cabinet maker’s triangle. Creating the bridal joints may seem complex first but it gets much clearer once you see the finished joint.

First I mark a notch at each end of the crosspiece – at 7mm parallel to the bottom edge and the length with the marking gauge set to the thickness of the side. I took the 90° side of my dovetail guide and sawed to my lines. Then I set the two cutters of the dual marking gauge to the thickness of the crosspiece and locked the setting. On the side pieces I eyeballed center and stroke the lines for the mortise. From my crosspiece I took the distance how high the mortise had to be. I began the mortise by sawing to the lines again with my pull saw. With a chisel and mallet, I removed the majority of waste and completed it by cleaning out the corners. Test fit looked pretty good, time to attach the handlebar to the pram.

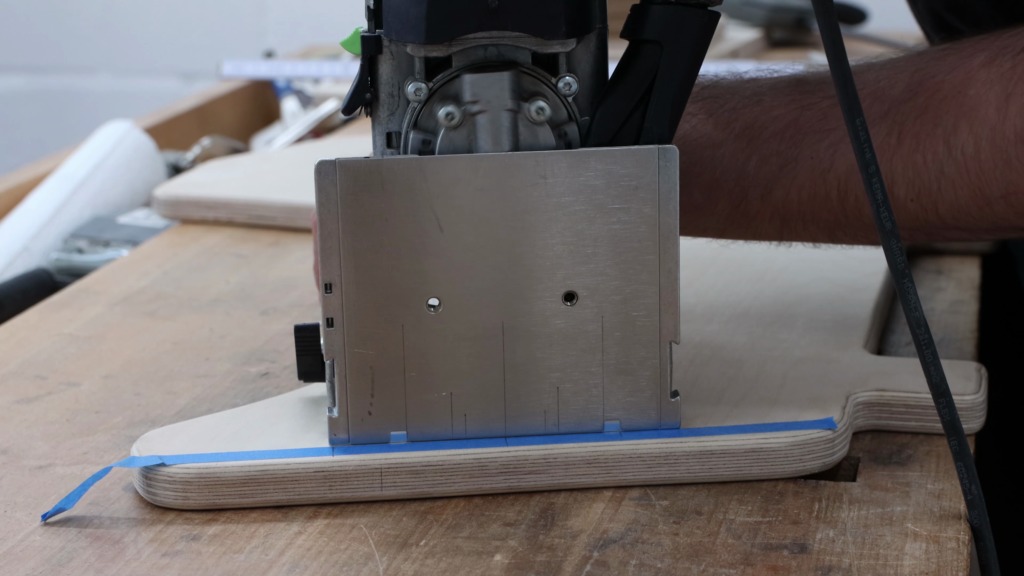

I positioned the sides of the handle parallel to the end of the pram with my combo square and since the plywood was already sanded I used tape to mark the position. For the domino location I used the same process as with the connecting pieces previously. And again freehand routing into both pieces.

There is something to Domino joinery that is soo satisfying.

Roundovers, surface prep and finish

After inserting my 7mm round over bit and setting up my router fence I rounded over all edges of the handlebar as well as the other parts. For the sides I had to remove the fence again. To make it appeal even nicer to children’s hands I sanded everything with 120 and 220 grid.

Alright on to the finish. Before applying anything I taped off the glue areas for later with painters tape. Then I primed all plywood surfaces. I started with the insides and added Dominos into the slots instead of using painter’s pyramids. This way one side could dry and I could already move on to the next side and the edges. I made sure the edges get an extra thick coat since they are thirsty.

I also applied primer to the wooden parts of the wheels I bought at the hardware store.

A waterbased lacquer was my choice as a finish since it is rated for toys and non-toxic once it has dried. My daughter wanted the pram to be blue, so I took a sky blue. A scrap piece with a few Dominos in it was a perfect drying rack.

After applying the second coat of lacquer I peeled off the tape and let the lacquer dry.

The next day it was time to glue it up. Usually, I am a bit nervous when it comes to the glue-up. But this one was so straight forward, that I felt comfortable moving around the camera. The Dominos make it easy and there was not much I could screw up. After adding some clamps I realized I taped off too much and touched it up with a small brush.

I used the drying time of the glue to assemble the wheels again and finish the handlebar. Again I used tape to keep the glue surfaces free of finish. After letting the finish sit for a solid 5 minutes I glued the handle to the pram and glued up the bridle joints as well. I came back a couple of hours later, sanded the joints flush, rounded over the remaining edges, and gave it another coat of finish.

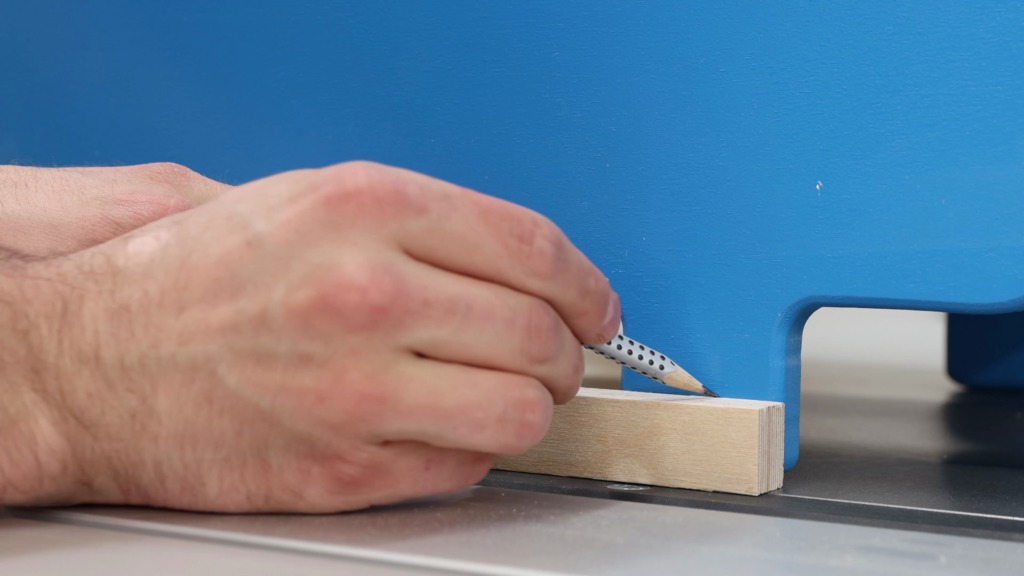

No racking with this little hack

In order to prevent the doll’s pram from racking, I sat it on the flat table of my table saw and marked the same relative height to the table with a piece of scrap. On this line I could drill the holes for the screws attaching the wheels. With an M4, a washer, and a lock nut I screw the wheels to the base.

Happy Birthday

I was very happy to finish this project on the last day before my daughter’s birthday and to have a present for her in time.

She absolutely likes it and she can take her dolls for a ride now.

Get the full set of plans and the printable full-sized template